Dimmer Moulding Ring (2/4/8/15/20/28 AMP)

Dimmer Moulding Ring (2/4/8/15/20/28 AMP) Specification

- Mold Base

- Standard industry mould base

- Cavity

- Single/multiple as per order

- Molding Material

- Electrical grade plastic/polymer

- Life Span

- Up to 100,000 cycles

- Tolerance

- 0.05 mm

- Precision

- High precision for secure fit

- Shaping Mode

- Other

- Material

- Other

- Type

- Other

- Surface Treatment

- Matte Finish

- Size

- Compatible with 2/4/8/15/20/28 AMP Dimmer

- Hardness

- High strength for electrical safety

Dimmer Moulding Ring (2/4/8/15/20/28 AMP) Trade Information

- Minimum Order Quantity

- 50-100 Pieces

- Payment Terms

- Cheque, Cash in Advance (CID)

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 2 Days

About Dimmer Moulding Ring (2/4/8/15/20/28 AMP)

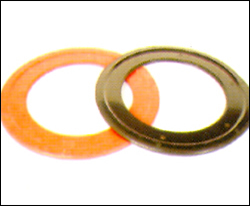

Winding Ring (2/4/8 amp)

Using latest process technology and high grade raw materials, our adept engineers manufacture a comprehensive assortment of Winding Ring (2/4/8 amp). These Winding Ring (2/4/8 amp) are fabricated in accordance to the prerequisite standards in order to ensure durable finish standards, high performance, corrosion resistance and longer life. Highly acclaimed for their reliability, our Winding Ring (2/4/8 amp) are available at market leading prices.

Specifications:

|

SPARES FOR VARIAC (DIMMER)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Optimized for Performance and Safety

With superior heat resistance and high dielectric strength, the Dimmer Moulding Ring delivers reliable safety in environments demanding high electrical loads. Its high-strength build and matte finish ensure durability while maintaining a professional appearance on switch plates and panels.

Precision Manufacturing for Secure Installation

Produced via injection molding using electrical grade polymers, these moulding rings are crafted with tight tolerances (0.05 mm) and standard industry mould bases. The precise engineering guarantees a secure fit for dimmer switches across multiple ampere ratings, minimizing installation errors and improving safety.

FAQs of Dimmer Moulding Ring (2/4/8/15/20/28 AMP):

Q: How is the Dimmer Moulding Ring installed on modular switch plates?

A: The ring is designed for panel or plate mounting, facilitating direct installation of rotary dimmer switches onto modular switch plates. Its precision tolerance ensures a snug and secure fit during assembly.Q: What ampere ranges are compatible with the Dimmer Moulding Ring?

A: It is compatible with dimmer switches rated at 2, 4, 8, 15, 20, and 28 AMP, offering flexibility for various electrical installations.Q: When should the Dimmer Moulding Ring be used in electrical setups?

A: This moulding ring is recommended for environments requiring mounting of rotary dimmer switches, especially where high electrical loads and thermal resistance are essential for safety and durability.Q: Where is the Dimmer Moulding Ring commonly used?

A: It is widely used in residential, commercial, and industrial modular switch panels across India, wherever rotary dimmers need robust mounting solutions.Q: What manufacturing process is used for the Dimmer Moulding Ring?

A: The ring is produced using injection molding with electrical grade plastic/polymer, enabling high precision and strength for each unit.Q: What are the benefits of using a Dimmer Moulding Ring with high dielectric strength and heat resistance?

A: High dielectric strength and heat resistance provide enhanced electrical insulation and durability, ensuring safety and reliable performance even in demanding, high-load environments.Q: How long can the Dimmer Moulding Ring be expected to last?

A: The product is engineered for longevity, with a life span of up to 100,000 cycles, supporting repeated use without compromising performance or safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Winding Ring Category

Winding Ring (60/100 AMP)

Minimum Order Quantity : 100 Pieces

Type : Other, Winding Ring

Surface Treatment : Electroplated

Mold Base : Steel

Material : Other, Copper Alloy

Hardness : High

GST : 07AFYPR9761E1ZK

|

|

VISHAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry