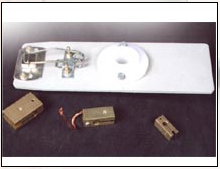

Dimmer Moving Armours Parts (15/20 AMP)

MOQ : 100 Units

Dimmer Moving Armours Parts (15/20 AMP) Specification

- Low Voltage

- 0V min

- Dimension (L*W*H)

- Approx. 60 x 35 x 30 mm

- Load Loss

- Minimal (<2W under full load)

- High Voltage

- 240V max

- Capacity

- 15/20 Amp

- Product Type

- Dimmer Moving Armours Parts

- Output

- Variable voltage adjustment

- Frequency (MHz)

- 50/60 Hz

- Efficiency

- >95%

- Phase

- Single Phase

- Usage

- Electrical dimmer circuits, power regulation

- Coil Structure

- Wound coil

- Coil Number

- Single

- Power Scope

- 15/20 Amp

- Weight

- Approx. 250 grams

Dimmer Moving Armours Parts (15/20 AMP) Trade Information

- Minimum Order Quantity

- 100 Units

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Units Per Week

- Delivery Time

- 7 Days

- Sample Available

- No

- Packaging Details

- Carton Boxes Packaging.

- Main Domestic Market

- All India

About Dimmer Moving Armours Parts (15/20 AMP)

Dimmer Moving Armours (15/20 amp)

We are instrumental in manufacturing and exporting an extensive range of Dimmer Moving Armours (15/20 amp) which is machined in adherence to prerequisite standards using excellent quality raw materials. Our entire range of Dimmer Moving Armours (15/20 amp) is in confirmation with International norms. Further, these are tested on the basis of well defined parameters before final delivery to ensure robust construction, uninterrupted performance and resistance to corrosion. Clients can buy these Dimmer Moving Armours (15/20 amp) in desired specifications and at reasonable prices.

Specifications:

|

SPARES FOR VARIAC (DIMMER)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Optimal Performance and Durability

Designed for high efficiency (>95%) and long-lasting durability, these Dimmer Moving Armours Parts are engineered to endure over 50,000 operational cycles. Their corrosion-protected, nickel-plated finish and robust mechanical sliding contact ensure consistent performance in varied indoor environments.

Versatile Application

Supporting a power scope of 15/20 Amps and compatible with popular devices like fan regulators and lighting dimmers, these parts are ideal for creating adaptable electrical dimmer circuits in both residential and commercial settings. Their variable voltage adjustment allows precise power regulation.

Easy Installation and Maintenance

The panel mount, screw-type design enables straightforward installation, while individual polybag or box packaging protects the product during transportation and storage. Maintenance is simplified by the durable construction and high insulation resistance, making these dimmer parts a long-term solution.

FAQs of Dimmer Moving Armours Parts (15/20 AMP):

Q: How do I install Dimmer Moving Armours Parts on panel mounts?

A: Installation is straightforwardsecure the unit onto the panel using the provided screw-type mounts. This ensures stability and reliable electrical contact for both residential and commercial applications.Q: What benefits do solid mechanical sliding contacts provide?

A: Solid mechanical sliding contacts ensure consistent and reliable conductivity, reducing wear over time and contributing to the high durability cycle of over 50,000 operations.Q: When should I replace Dimmer Moving Armours Parts?

A: With a typical service life exceeding 5 years and a durability rating of over 50,000 cycles, replacement is generally only needed if physical damage or irregular performance occurs.Q: Where can these dimmer armours be used effectively?

A: These parts are intended for indoor installations within residential and commercial environments, especially in fan regulator or lighting dimmer circuits operating on single-phase 50/60 Hz frequency.Q: What steps are involved in the maintenance process?

A: Maintenance involves periodic inspection for dust or debris, ensuring mounting screws remain tight, and checking that sliding contact surfaces are clean to preserve efficiency and electrical safety.Q: How does nickel-plated surface finish offer protection?

A: The nickel-plated surface finish provides excellent resistance to corrosion, prolonging the lifespan of the dimmer armours, notably in humid or potentially corrosive indoor environments.Q: What is the main advantage of using these parts in electrical dimmer circuits?

A: They offer highly efficient (>95%) variable voltage regulation with minimal energy loss, allowing precise control of lighting or fan speed while maintaining electrical safety and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Dimmer Moving Armour Category

GST : 07AFYPR9761E1ZK

11/10, Lower Ground, New Rashid Market, Krishna Nagar, Street No-6, Delhi - 110051, India

Phone :07971190956

Mr. P. R. Jaiswal

(Proprietor )

Mobile :07971190956

Mr. P. N. Jaiswal

Mobile :07971190956

|

|

VISHAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry