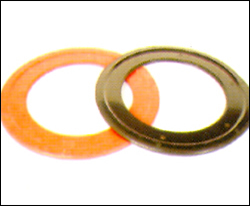

Winding Ring (60/100 AMP)

Winding Ring (60/100 AMP) Specification

- Mold Base

- Steel

- Cavity

- Single

- Molding Material

- Copper Alloy

- Tolerance

- 0.05 mm

- Life Span

- Long Life (Over 500,000 cycles)

- Precision

- High Precision

- Shaping Mode

- Injection Molding

- Material

- Copper Alloy

- Type

- Winding Ring

- Surface Treatment

- Electroplated

- Weight

- Approx. 32 grams

- Size

- Standard (Fits 60/100 AMP)

- Hardness

- High

Winding Ring (60/100 AMP) Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 2 Days

About Winding Ring (60/100 AMP)

Winding Ring (2-100 amp)

With rich industrial experience, we specialize in manufacturing, supplying and exporting a quality approved range of Winding Ring (2-100 amp in affordable costs. Our trained and experienced technocrats design & develop these Winding Rings (2-100 amp)as per the specifications of clients using best quality raw materials and advanced equipments. Sturdy in design, reliable and optimum in performance, these Winding Rings (2-100 amp) have a longer service life and can be availed by clients at pocket friendly prices.

Specifications:

Tool No | Disc | Suitable for Swg | Core Size |

1035 | 2 Amp | 28/29 | 50 X 100 |

1002 | 4 Amp | 22 | 76 X 152 |

1003 | 6 Amp | 21 | 76 X 152 |

1004 | 8 Amp | 19 | 76 X 152 |

1054 | 10 Amp | 18 | 76 X 152 |

1005 | 15 Amp | 17 | 96 X 198 |

1058 | 20 Amp | 16 | 96 X 198 |

1011 | 23 Amp | 15 | 96 X 198 |

1060 | 25 Amp | 14 | 96 X 198 |

1062 | 28 Amp | 14 | 163 X 273 |

1026 | 30 Amp | 13 | 163 X 273 |

1056 | 35 Amp | 12 | 163 X 273 |

1007 | 40 Amp | 11 | 163 X 278 |

1061 | 60 Amp | 10 | 163 X 278 |

1009 | 100 Amp | 9 | 234 X 345 |

1010 | 200 Amp | 6 | 234 X 345 |

1033 | 20 Amp | 16 | |

1042 | 10 Amp | 18 | |

1063 | 40/60 Amp cup Type | 10 | 160 X 278 |

1064 | 100 Amp cup Type | 9 | 234 X 345 |

Exceptional Conductivity and Durability

Built from premium copper alloy and electroplated for enhanced resistance, our Winding Ring guarantees superior electrical conductivity and extended operational life. Its single-cavity, high-precision design ensures optimal performance in demanding settings such as switchgear and industrial panels.

Precision Engineering for Reliable Performance

Manufactured using steel molds and precise injection molding processes, these winding rings adhere to strict tolerances for consistent quality. Each ring is quality-checked to meet the demanding requirements of electrical distribution applications, making it a dependable choice for professionals.

FAQs of Winding Ring (60/100 AMP):

Q: How is the Winding Ring (60/100 AMP) utilized in electrical panels and industrial distribution?

A: The Winding Ring is installed in electrical panels, switchgear, or industrial distribution systems to establish reliable electrical connections. Its superior conductivity and precise fit make it essential for managing and distributing current effectively in high-load environments.Q: What material is used in the manufacturing of the Winding Ring, and why?

A: This winding ring is crafted from high-quality copper alloy, selected for its remarkable electrical conductivity and corrosion resistance. The addition of an electroplated surface further enhances durability in harsh industrial conditions.Q: When should I consider replacing a Winding Ring in my equipment?

A: Although designed for a long operational lifespan (over 500,000 cycles), the ring should be inspected regularly for physical wear, visible degradation, or loss of conductivity, and replaced promptly to maintain optimal system safety and efficiency.Q: Where can the Winding Ring (60/100 AMP) be sourced from?

A: This product is available through reputable manufacturers and suppliers in India, specializing in high-precision copper alloy electrical components for industrial and commercial use.Q: What is the manufacturing process behind the Winding Rings high precision and durability?

A: The ring is produced using an injection molding technique with a steel mold base, ensuring tight tolerances (0.05 mm) and high hardness. The copper alloy material contributes to both mechanical strength and exceptional conductivity.Q: How does the electroplated finish benefit the Winding Ring during its lifespan?

A: The electroplated surface provides excellent corrosion resistance, ensuring that the winding ring maintains its structural integrity and electrical performance even in harsh or corrosive industrial environments.Q: What advantages does using a high-precision Winding Ring offer to electrical systems?

A: Utilizing a high-precision Winding Ring ensures efficient current transfer, reduced energy losses, and increased system reliability, resulting in smoother operations and decreased maintenance needs for electrical infrastructure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Winding Ring Category

Dimmer Moulding Ring (2/4/8/15/20/28 AMP)

Minimum Order Quantity : 50100 Pieces

Surface Treatment : Matte Finish

Molding Material : Electrical grade plastic/polymer

Cavity : Single/multiple as per order

Size : Compatible with 2/4/8/15/20/28 AMP Dimmer

Material : Other

GST : 07AFYPR9761E1ZK

|

|

VISHAL ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry